Rooms for Improvement

Rooms for Improvement

Rooms for Improvement

the entertainment spaces in this Australian home are undeniably spectacular—but after a decade in use, they were ready for a major sonic makeover

the entertainment spaces in this Australian home are undeniably spectacular—but after a decade in use, they were ready for a major sonic makeover

by Michael Gaughn

by Michael Gaughn

October 31, 2022

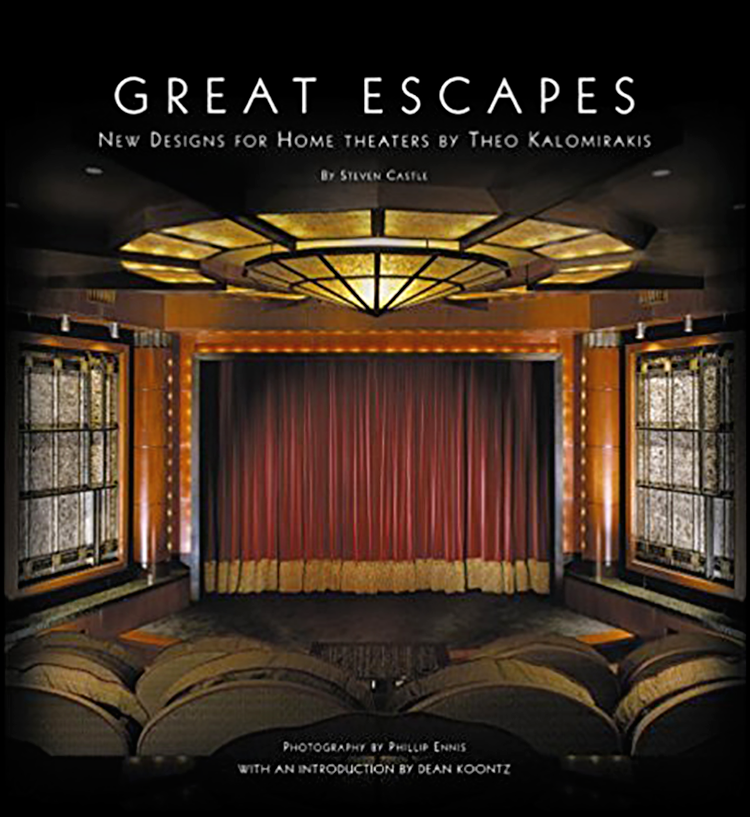

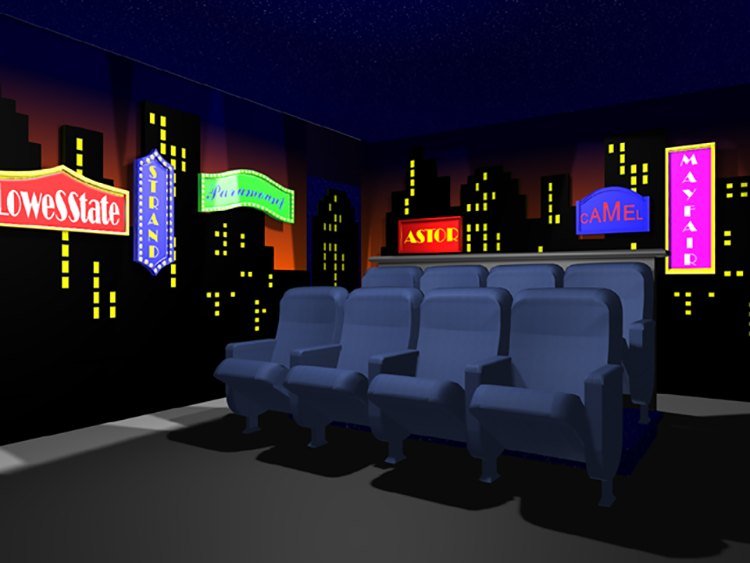

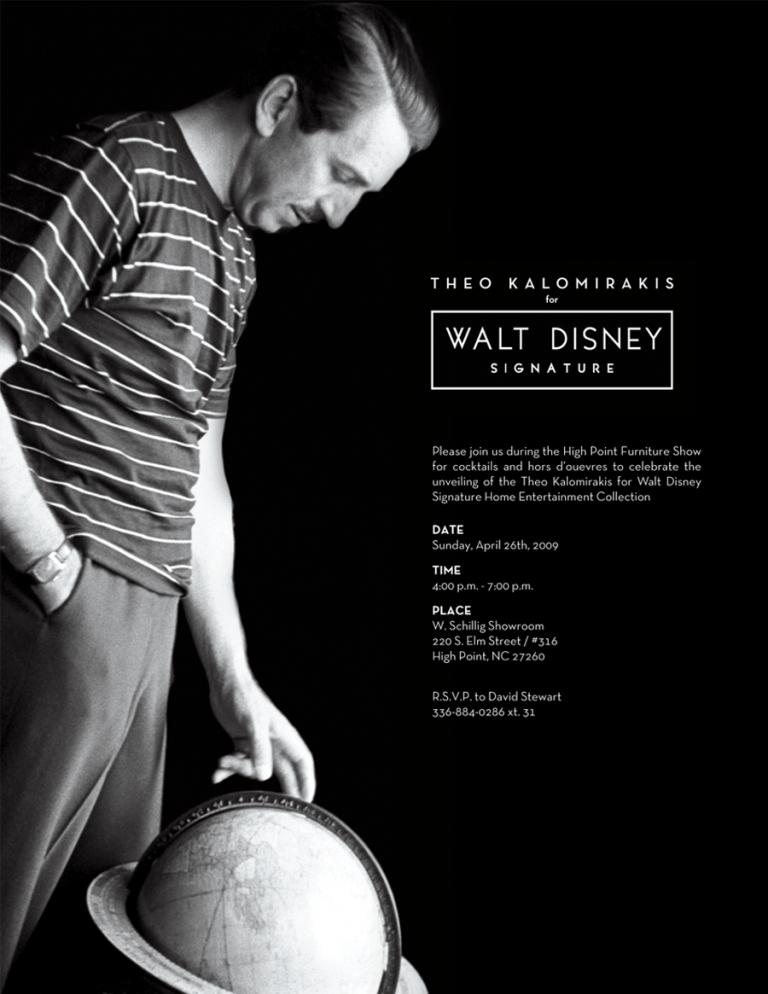

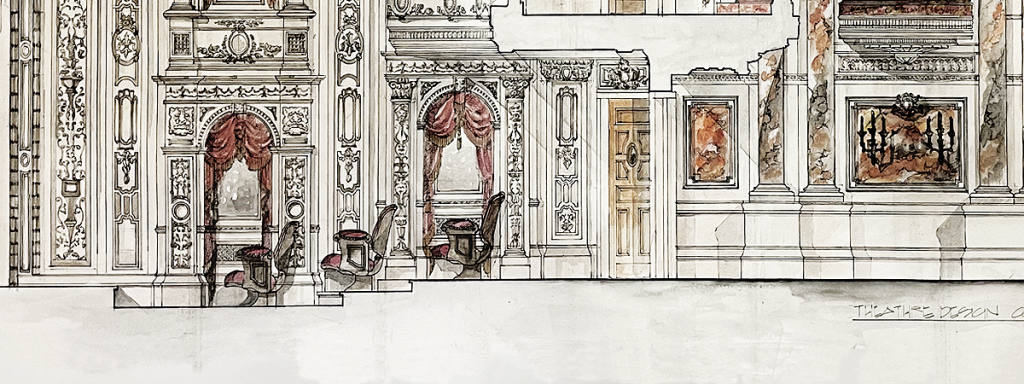

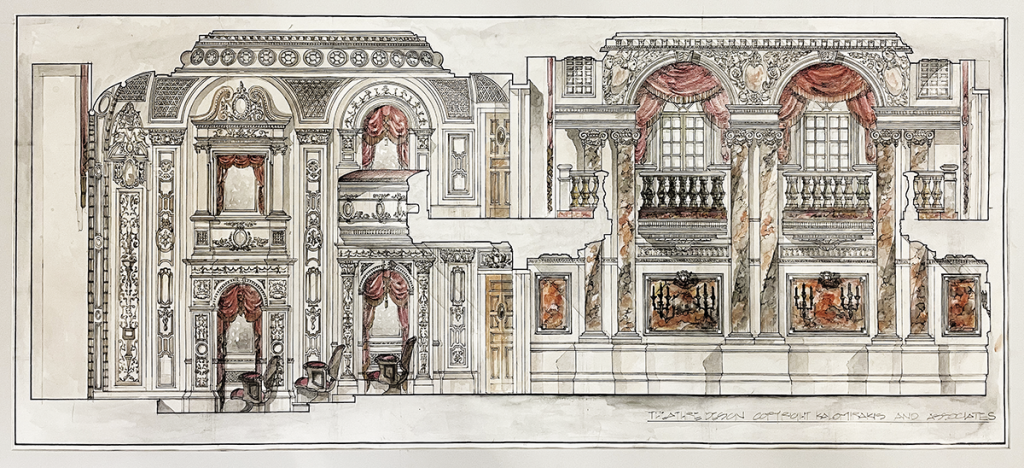

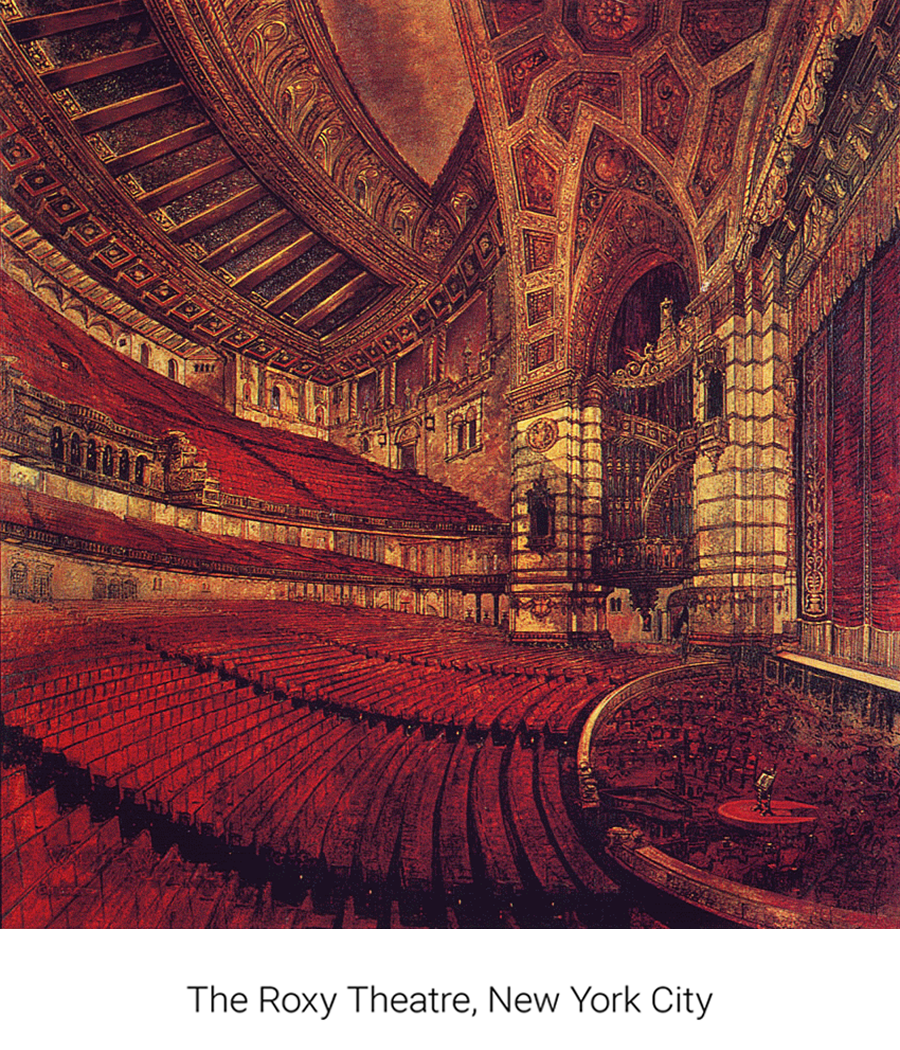

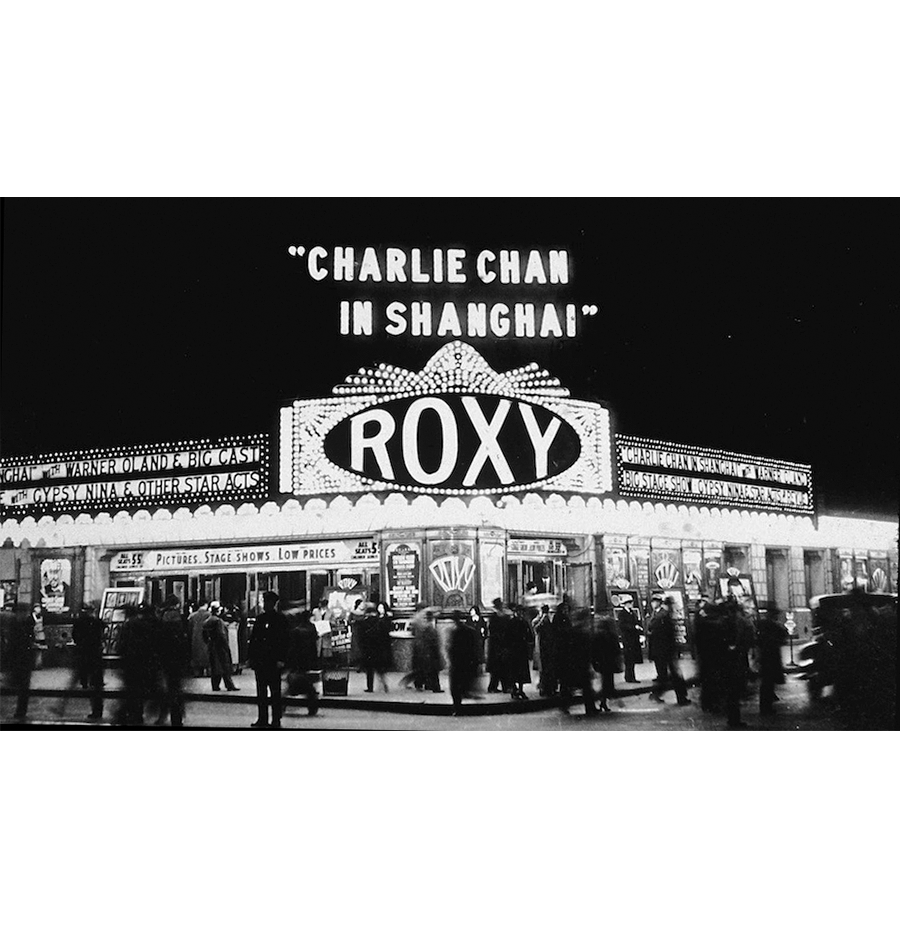

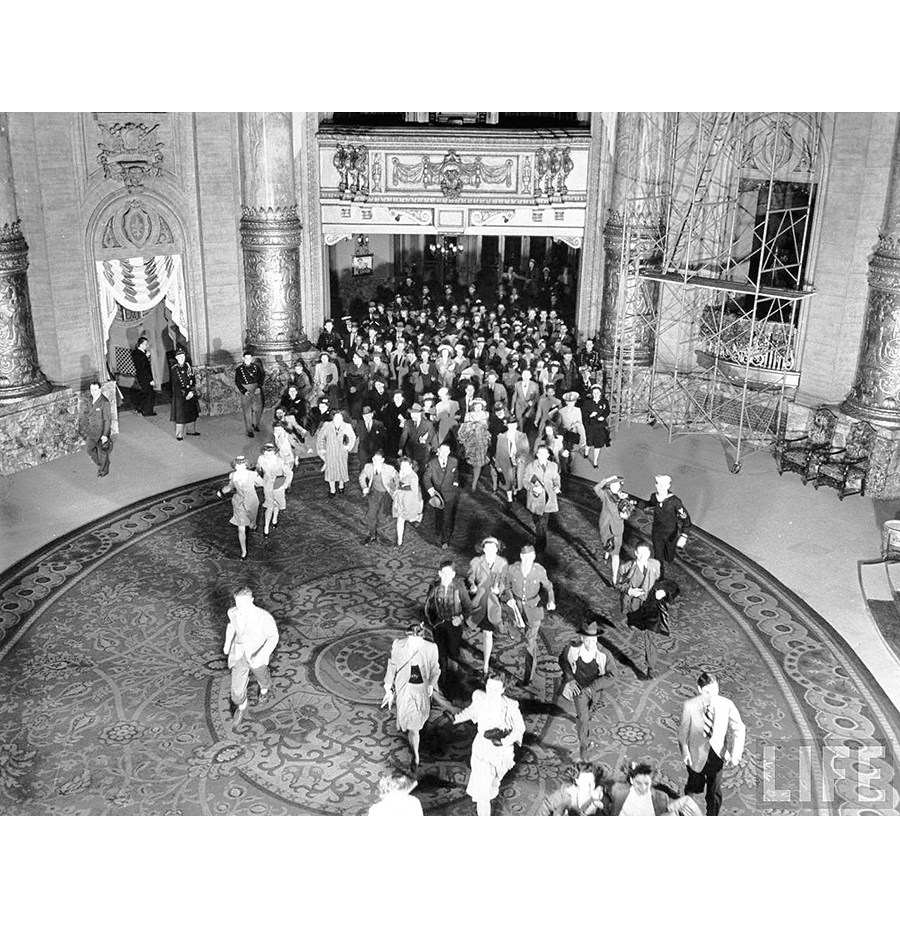

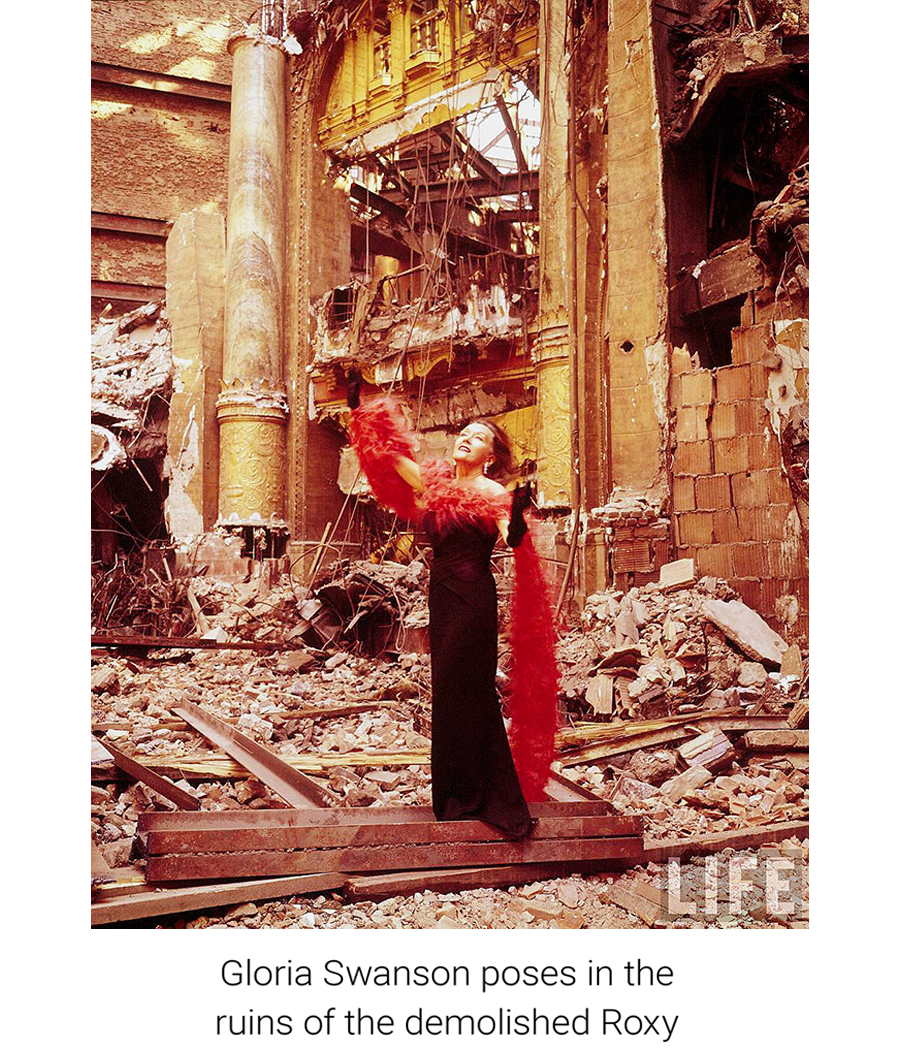

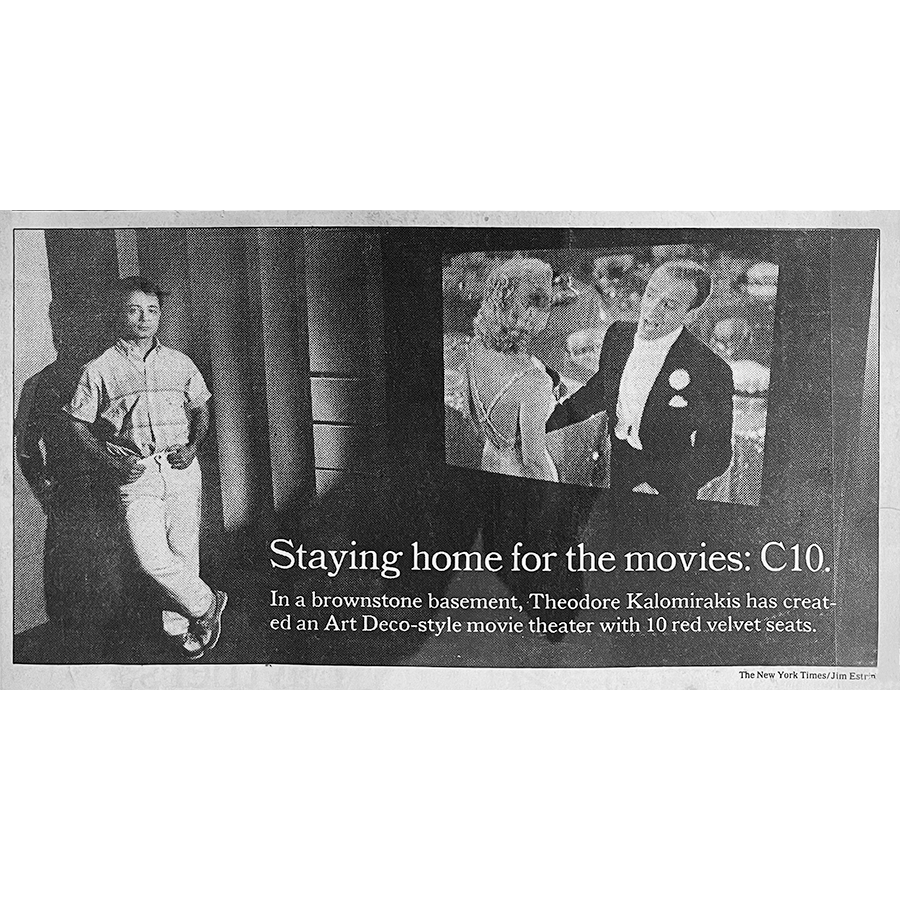

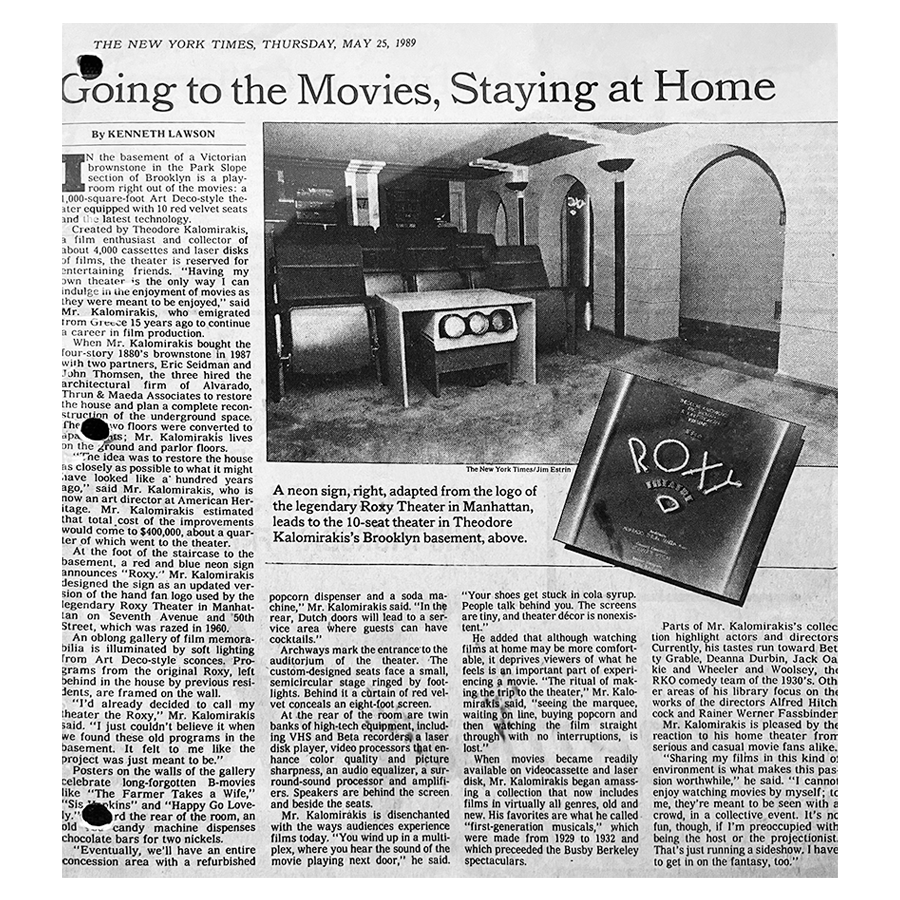

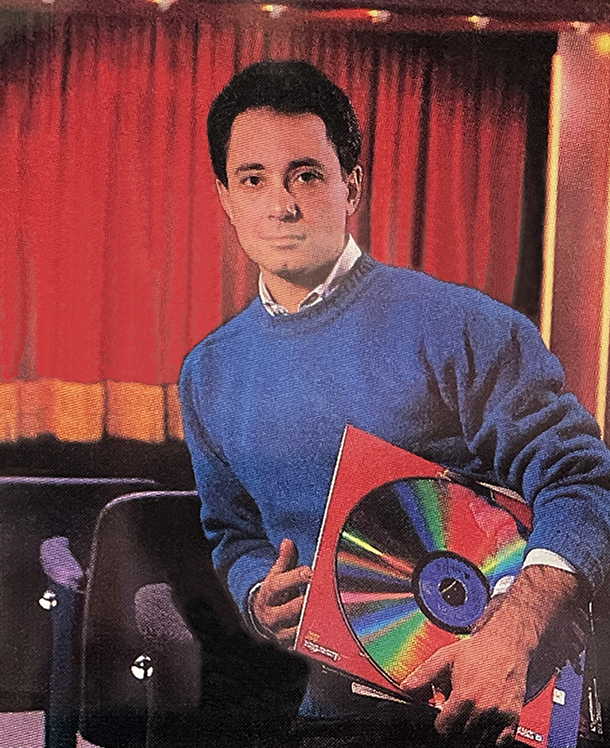

This story could have easily just been about the Theo Kalomirakis-designed Art Deco home cinema. Or it could have focused instead on the jawdropping one-of-a-kind entertainment area, with its discreet stage, ability to accommodate 250 guests, and epic views of Sydney Harbor. But there turned out to be an even bigger—though not quite as showy and obvious—story to be told, about how these kinds of high-end spaces have become so elaborate and flexible and the trends and technologies influencing and supporting them are evolving so quickly, that we’re now being presented with an unprecedented array of opportunities—but also the continual challenge of staying ahead of the curve.

Every home cinema is a completely custom and unique machine. And the open-floorplan multi-use entertainment areas that are beginning to supplant dedicated theater rooms (like the one profiled in “Achieving Serenity”) are even larger and more complex machines that have to be able to handle a wider and wider variety of tasks. You don’t need to be a techie or have any interest in what’s going on under the hood to realize that creating something like that and keeping it functioning optimally means relying on massive processing power. The key thing to remember is that these systems are basically one-off computers and subject to all the thousand shocks and upgrades our digital brethren are heir to.

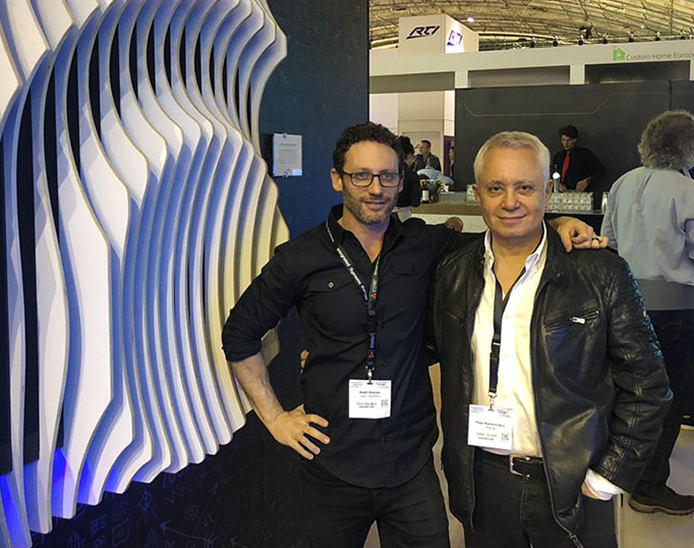

Because of that, this is also a story about not the visible but the invisible. As spectacular as these rooms are, they’re literally useless unless someone keeps a constant and careful eye on all manner of things that are never seen by their users. Acoustical designer Steve Haas has developed a reputation as a master of that unseen realm, one of a you-can-count-‘em-on-the-fingers-of-one-handful of people who know how to not just tame but maximize these intricate, individually crafted mechanisms so they can achieve and maintain peak performance. The portfolio of his company, SH Acoustics, extends well beyond private residences to museum and commercial venues as well, and Haas found himself having to draw extensively on that broader pool of knowledge in order to make this Australian homeowner’s exceptional mandate a reality.

A VERSATILE PERFORMER

The seven levels that constitute this 55,000-square-foot residence—let’s call it the Sydney Home—rest terraced in a rock face overlooking the harbor, with the iconic bridge and opera house prominent in the dioramic views from its primary living spaces and numerous terraces. It shouldn’t be a surprise to hear that a home of this caliber would hold a theater from a premier designer like Kalomirakis, nor that Haas, who has collaborated on some of Theo’s most ambitious efforts (including the legendary Paradiso) should have been called in to handle the acoustic and audio chores.

The entertainment area, with its spacious bar & lounge area and terrace with epic views of Sydney Harbor, can comfortably accommodate 250 guests

The stage area, with the main speakers hidden behind the fabric at the top of the proscenium. Steve Haas took the client to the Steinway showroom in New York to help him select the Model B grand piano.

The home has seen performances by numerous A-list artists, including Sting, Michael Bolton, and Australian native Delta Goodrem (above)

“Once I had some dialogue with the client, we realized there was a need to have me consult on other keys areas of the home,” says Haas, “especially what they call the Level 1 entertainment space.” It’s not unusual for a home of this size to have a place for holding parties, hosting events, and staging live performances, but you’d be hardpressed to come across another similar space as well realized or as chameleon-like as the one here.

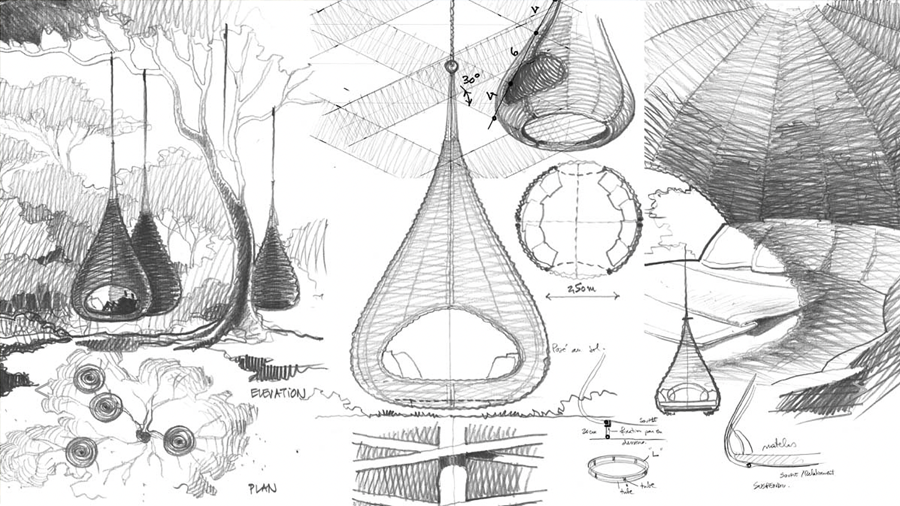

The room gives few clues to its other capabilities when they’re not in use, feeling causal, comfortable, and domestic. Furniture groupings and large canvases help disguise the stage’s true identity, with the main speakers for performances hidden behind fabric panels in the soffit above the proscenium, and with a dropdown projection screen and monitor speakers tucked into the ceiling of the stage area.

The client’s desire to have the room provide exceptional sound for parties, fundraisers, and other large events as well as for both movies and live entertainment created a unique challenge for Haas since each use had its own set of not necessarily cross-compatible needs. The music for parties had to be able extend into the bar area, out onto the various terraces, and into other parts of the home as well, while the stereo sound for performances needed to match what you would expect to hear in a high-end nightclub, and the movie system had to supply satisfying surround for groups as large as you’d find in a commercial cinema—all in a wide-open room filled with glass, wood, and other structural and decorative enemies of quality sonic reproduction.

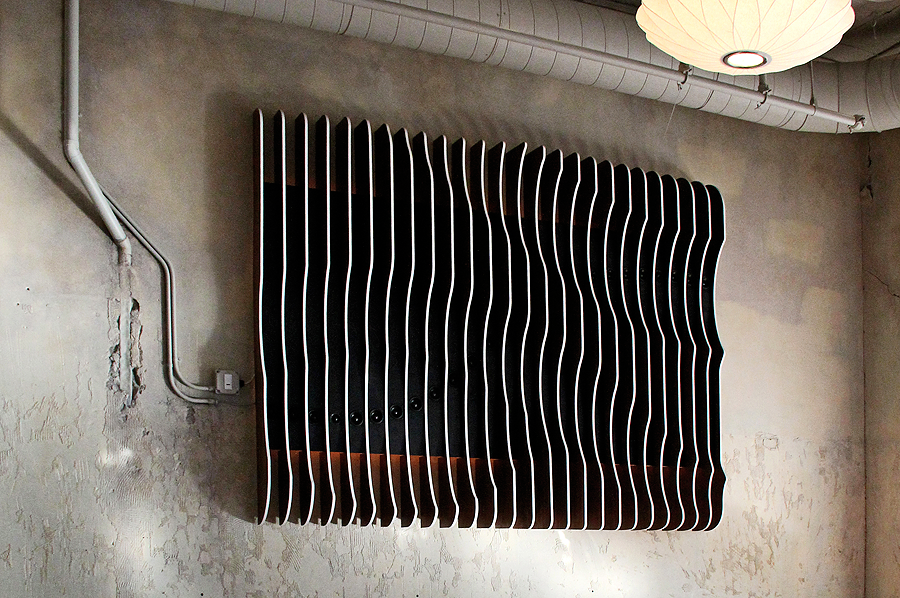

Haas was especially concerned about architect Alec Tzannes’s design for the ceiling, which used suspended elongated 3/4″ rectangular slats to create a barrel vault that would conceal the multitude of speakers, subwoofers, lighting cans, and ducts. “The client actually flew me over to Sydney to make the case,” says Haas, “because he had consulted with a local acoustic expert who had said there would be no problem. And I looked at it and said, no. This is absolutely wrong.” His solution was to use round dowels instead. “After we did our calculations and I created a physical mockup of the dowel system, we saw that the sound would bend around them in a way that would have a negligible effect.”

The curve of the ceiling was also a problem since it would tend to reflect and focus the sound from the speakers instead of spreading it evenly throughout the room. To help address that, and all the many reflective surfaces, Haas took advantage of the space above the dowels to apply extensive sound absorption.

Not only have the homeowners and their guests been impressed with the result, so have the numerous A-list artists who have sung there—Sting, Michael Bolton, and Australia’s Delta Goodrem among them. “Michael Bolton said it was one of the best-sounding places he’s ever performed in,” says Haas.

MIXED SIGNALS

Cut to a decade later. The homeowner tells Haas he’s concerned the digital signal processors (DSPs) tasked with handling all the various audio responsibilities are beginning to fail. It’s not that the gear is faulty—it’s just at the end of its lifespan. “It’s not uncommon to see DSPs fail after 10 years,” says Haas. “They’re essentially computers, of course”—which means they’re just as likely to start crapping out as any laptop or desktop PC. And they’re subject to the same rapid technological advancements, with all their inevitable upgrades. Staying a step ahead of the upkeep is just a fact of life with anything this diverse and complex.

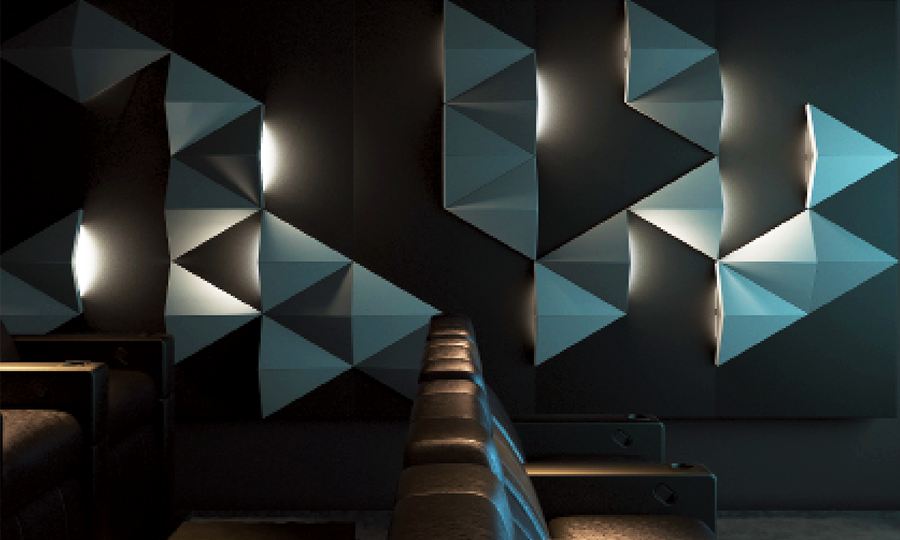

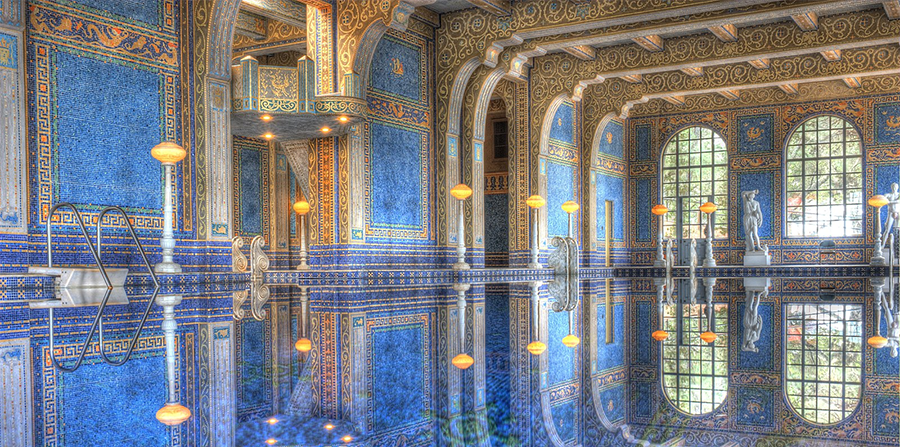

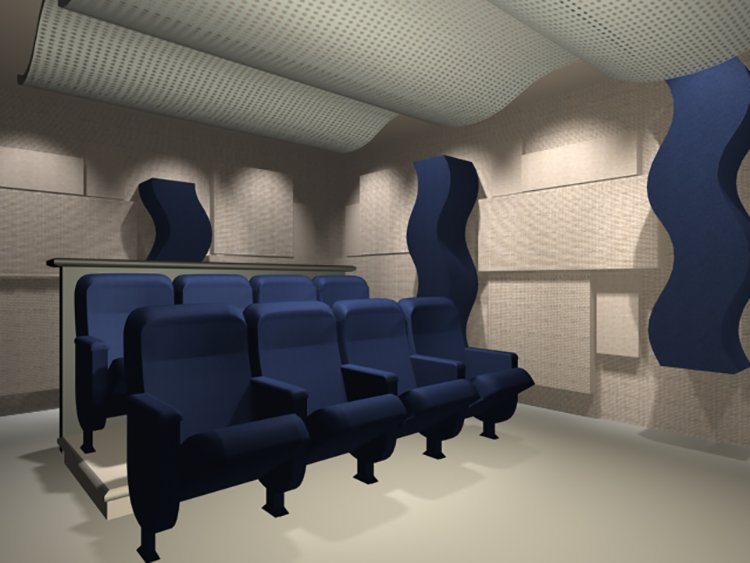

The 7.1-channel surround sound system in this Theo Kalomirakis-designed home theater was recently upgraded to Atmos via the addition of eight Wisdom Audio ceiling speakers

PROJECT TEAM

acoustical designer

Steve Haas

SH Acoustics

theater designer

Theo Kalomirakis

TK Theaters

custom integrators

Datascene

architect

Alec Tzannes

Haas saw the task as not a chore but an opportunity to bring all the various types of DSP currently in the house under one brand and system. And while he was at it, why not upgrade the private cinema to Atmos as well?

With its 7.1-channel California Audio Technology speaker array, the cinema had been serving the homeowners well since its inception in the early ‘00s. But, having been impressed by Wisdom Audio’s ceiling speakers, Haas felt that adding eight of them to the room to create an Atmos configuration would significantly enhance the movie-watching experience. And the speakers were compact enough that he could have them installed without having to engage in a massive do-over.

Not that the upgrade wasn’t a challenge. Because they couldn’t dismantle the whole ceiling, Haas wasn’t sure what he, the contractors, and the custom integrators from Sydney-based Datascene would find when they attempted to tap into the preferred speaker locations. So they adopted a surgical approach, working their way carefully around the duct work and other impediments. And because there are bedrooms just above the theater, a tremendous effort had been made during the original construction to ensure none of the sound would bleed through the ceiling. Honoring this, they kept as much of the existing treatments in place as possible as they added the new speakers, also providing sound-isolation caps in each of the speaker locations.

Premium theaters like this one often rely on a tip-top-of-the-line sound processor from a company like Storm Audio or Trinnov. But Haas went with a Marantz AV8805 instead because it provided the desired sound quality without all the additional bells and whistles of the higher-end models and would more readily work in tandem with the QSC Q-Sys pro-audio DSP he was deploying throughout the other key areas of the home.

It was also time to replace the projector—and rebuild the projection booth, which, located near the cliff face, had been infiltrated by moisture. Haas helped the client pick the new projector, consulting with Barco and coming back with a recommendation for its Wodan model. But this required an acoustical makeover for the booth since the new projector was significantly louder than the previous one and the noise would have been distracting, especially for anyone sitting in the last row, which rests up against the booth wall.

Acoustical designer Steve Haas calibrating the sound for the Level 1 entertainment area.

Acoustical designer Steve Haas calibrating the sound for the Level 1 entertainment area.

Sign up for our monthly newsletter

to stay up to date on Cineluxe

At 38 feet, the room is unusually deep for a private theater. “In a room like that,” says Haas, “you can get so sonically disconnected from the front that by the time you get to the rear seats, it feels like you’re in a different space.” To address this, he used acoustical treatments to disperse the sound so that the experience would be the same no matter where someone is sitting.

For all the defining trends the Sydney Home represents, maybe the most significant is its extensive blending of consumer and pro gear. As high-end homes incorporate more elaborate entertainment areas like dance floors and live-performance spaces, they need to be able to provide sound on par with what artists expect in professional venues—along with the ability for DJs, sound mixers, and others to be able to jack in their gear.

Also, a multiform multipurpose system as flexible and complex as the one here can quickly exhaust the abilities of the hardware available on the consumer side of things. It often takes robust, function-specific professional gear to rise to these emerging challenges.

Haas, who is just as comfortable working on recording studios, concert halls, and galleries as he is on domestic environments, turned out to be the ideal fit for a project this ambitious. As a member in good standing of that previously mentioned acoustical elite, he was able to bring the necessary combination of expertise and experience to bear. Relying on someone whose knowledge is limited to the residential world to master something like this is a sure-fire recipe for disaster. Since entertainment areas are only going to get bigger, more versatile, and exponentially more complex, better to place them in the hands of people like Haas who not only think, but perform, well outside the home theater box.

Michael Gaughn—The Absolute Sound, The Perfect Vision, Wideband, Stereo Review, Sound & Vision, The Rayva Roundtable, marketing, product design, some theater designs, a couple TV shows, some commercials, and now this.

© 2023 Cineluxe LLC